|

Swisscompact

Equipment for production with three-component epoxy. The A component is heated directly in the drum and is then transferred into the component holders using a pump with a trailer plate. All components have flow rate control. The A component is as hard as stone at ambient temperatures. The C component must be kept cold (20°C) until it comes into contact with the other components which required a special construction in the blender head. The blender head traverses in the X axis to feed the mixture to the applicator roll. This mixture is so dangerously explosive that various safety elements had to be incorporated. Some features

- A and B components hard, 5,000 pas, in the cold condition!!

Transportable feeder and metering unit for blending and metering of a two-component epoxy resin. The containers can be connected with snap couplings. This also applies to the blender head. The unit is small, compact and built for easy transport by truck. It has the exact dimensions for a transport pallet. Some features

- Unit for blending and metering of epoxy resin

|

|

Application Swisscompact

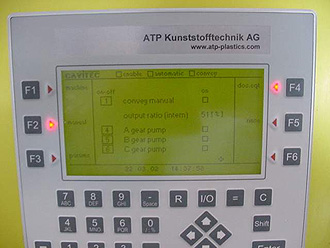

Graphic display option with function key pads. Partially with numeric-code protected access regions.  200 Ltr. Delivery unit with silicon heater and level indication.

The high and exact fusion temperature required a constructional change to the trailer plate, where the homogeneity has also to be maintained at the pump mouth.

This blender head is for three-components with static blending and flushing. Heating for blender head and blender. The head is mounted on a carriage which traverses across the feeder roll and distributes the mixture homogeneously. |