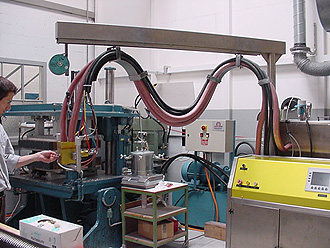

Beschrieb:

Blending and metering units for the processing of thermoplastic resin systems such as polyamide 6,

polyamide 12, PBT, etc. The unit shown above was built for laboratory use. Equipment can be built for

continuous or step-wise processing. The monomer is loaded into the container in the form of powder or

pills, then melted and conditioned following a multi-step controlled heating cycle. It is then ready

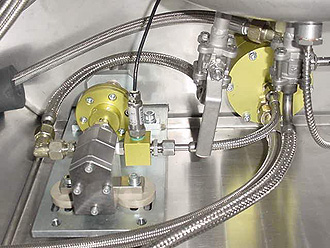

for processing. A minimal quantity of the catalyzing agent is measured and continuously fed in using

a specially constructed valve and mixed homogenously. This casting precursor is then cast into the mold.

This blending and metering unit (illustration) is applicable for working with PBT or polyamide 12.

- Unit can be driven with control rods

- Protection of components with nitrogen shroud

- Mischungsverhaeltnisse von 100 : 0.5 bis 100 : 4.0, programmierbar

- Temperature monomer up to 200°C max.

- Temperature activator/catalyzer 20°C; feed using flow metering

- Continuous homogenous oil heating

- Blending static, blender head mobile along X and Y axes

- Start casting and flushing using press button on the blender head

- Flushing with poison-class free flushing fluid supplied directly by the ATP company

- Productivity 100 g/min. - 1000 g/min. or per customer requirements

- Heater cell heated using heat exchanger and air circulation

- Homogenous temperature via a special air circulation in the heater cell

(patent pending)

- Blending static - heated

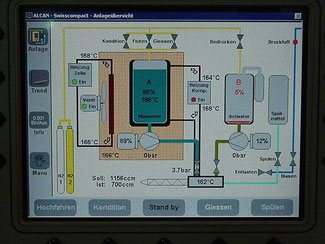

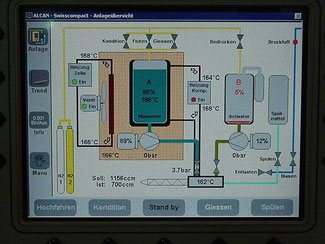

Industrial PC with mimic diagram and function cycles which can be selected using the push buttons.

Control

All operating, control and adjustment functions are carried out using the industrial PC built into

the equipment. Casting diagrams can be depicted; data can be stored, or burned onto a CD. The computer

can also be patched into a network. All operating parameters and settings can be simply keyed in from

the control panel.

The functions are organized in cycles and can be called up and

activated using the function keys.

- Run up (heat up)

- Cast

- Flush

- Stand by

- Manual

- Service

- Error history

The computer is visualized via a graphic option display with mimic. All significant parameters can be read off.

- Levels

- Temperatures

- Operating conditions

- Shot quantities

- Active elements/cycles

|